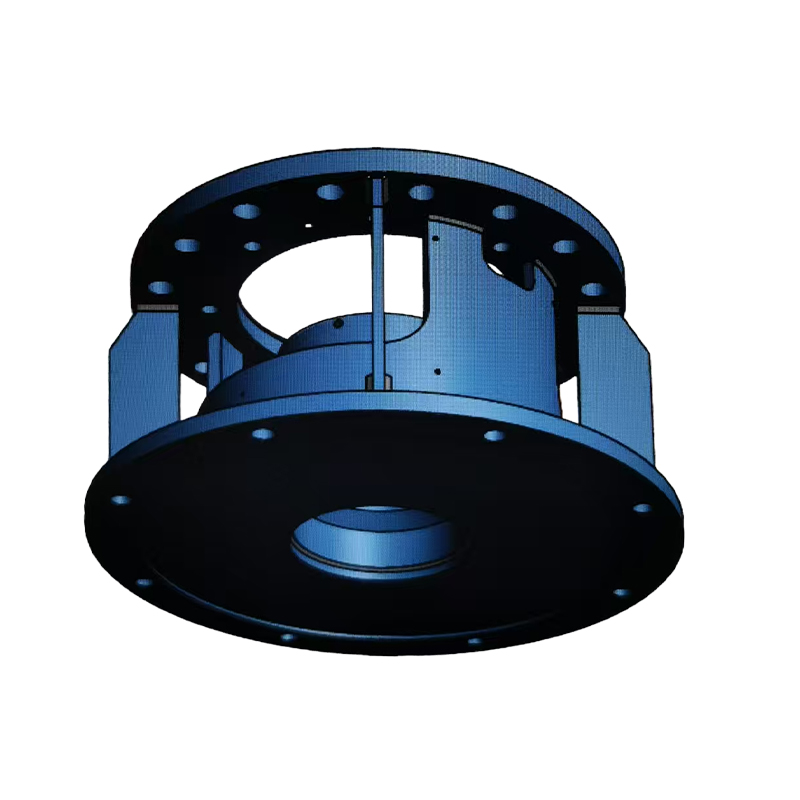

Hardware accessories customization must achieve a high degree of synergy between high strength, wear resistance, and precise fit tolerances—withstanding continuous impact and heavy stress, enduring long-term friction and wear, and seamlessly assembling wi

- +86-13719254738

- ningkangcnc@126.com

- Room 103, 104, Building 24, Wanyang Wanzhong Park, No. 2 Huabao East Road, Xinhua West Village, Longjiang Town, Shunde District, Foshan City